How Is Jewelry Made? A Guide to Jewelry Making Techniques

Mazlan has an affinity for insightful facts that he loves to share with others.

Jewelry Making

You must have admired many rings, bracelets, necklaces, and other precious jewelry and wondered how they were so beautifully made and crafted. Who were the talented artisans that wielded their skills and creativity to breathe life to these gemstones? How were they set?

For many of us who have taken for granted these refined and elegant crafts of jewelry making, here is a quick guide to how jewelry is made. A glimpse behind the scenes of designing and creating jewelry will not only leave you in awe but wondering when you can afford to buy them!

Jewelry Making: The Early Days

In the early days, jewelry was fashioned and made from stones, metal, bones, wood, and other attractive materials available within the country. The artisan would spend days hammering, pounding, and chiseling an intricate design to get the desired shape and size.

Some of these ancient jewelry-making techniques use several ingenious methods. Methods that were commonly used in the early days are now considered a specialty skill.

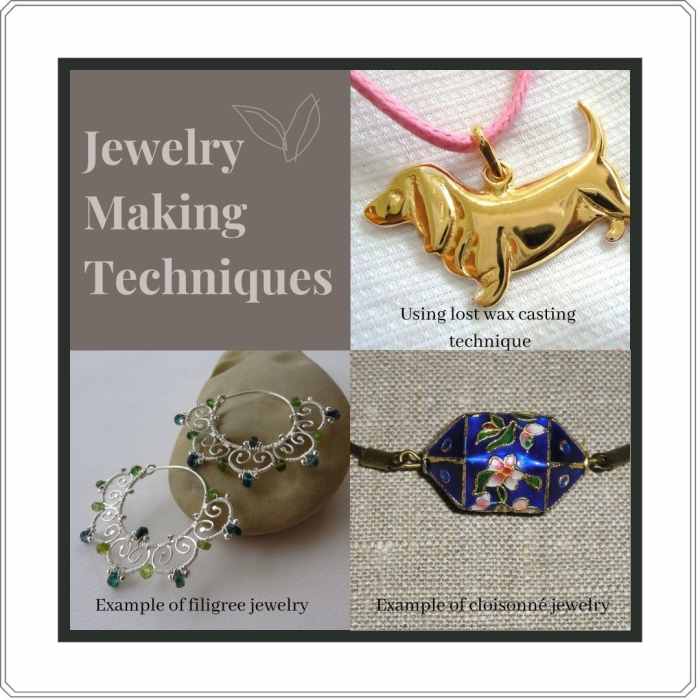

Filigree Jewelry

Among the many techniques is filigree. Filigree is when materials such as silver, copper, or gold are heated and poured through small holes to create thin wires. The artisans then wind these wires to create patterns such as animals, flowers, or just a simple curved pattern.

It is a difficult technique that requires patience and a steady hand. Filigree jewelry was very popular in the early 1920s and is still popular to this day.

Cloisonné Jewelry

Cloisonné is another ancient technique where pieces of glass are inserted in an open compartment in metals. It is then heated at a high temperature to create an elaborate design of vibrant color.

Cloisonné technique is popular in China and Japan and a very well-crafted cloisonné enamel object can be quite expensive.

Lost Wax Casting for Jewelry Design

The lost wax casting process involves carving the jewelry design in wax. It is then covered with clay and baked until the clay mold is hard. Through a small hole, the hot wax is poured out. The artisan then pours the molten metal, which could be silver or gold, into the mold to cast the jewelry.

This technique is still being used today as it is the easiest and the most cost-efficient. If you attend classes on how to make jewelry, this is usually one of the techniques taught.

How Is Jewelry Made Today?

Today, jewelry is produced using a combination of several methods. It uses the traditional method of using simple tools to modern and sophisticated tools that are sometimes computer-controlled.

Despite all these, skill and creativity remains the most important tool for any jewelry artisanship. Jewelry involves several processes, and these can be long and slow procedures.

Let us look at the steps taken from concept to final product in jewelry making.

Jewelry Design Ideas

In any product, you have to conceptualize the design first. Likewise, in the jewelry making process, designers will be briefed on the required product and its uses. For example, the designer will be told to come out with a ring design for Valentine's Day using diamonds and white gold.

They will then sketch out the design, and once approved, the jewelry crafting can start.

Read More From Bellatory

Jewelry Tools

This approved design will be handed over to the model maker. In some companies, several jewelry artisans will specialize in certain design. If this is the case, the artisan with a specific skill and talent will be assigned to do the molding and casting, whose expertise is best suited to create this particular jewelry.

Jewelry Molding

The artisan will then transform the design into a master mold. This is the most crucial part, as the results will depend on this mold.

This old tradition is still done by hand, especially for one of a kind design piece. This process can vary from a few days to a few months depending on the complexity of the design, which may require more detail and delicate shaping works.

The selection of material used for the mold is also important. Natural rubber, silicone, and wax are the most popular as they are the cheapest. For an intricate design that requires several tweaking then jewelry molding wax will be used as it is pliable and easy to work on,

Metal is another material that is used as a mold, but it is the most expensive. However, it has better accuracy, consistency, and precision. Some company uses gold as a mold when they need fast work. Silver, being the most economical of all metal for this molding process, will be used if the mold is reused more than once. Jewelry that is molded with metal is naturally more expensive.

Jewelry Casting

This is another complex process. The jewelry casting wax mold is placed in a steel container, which is then filled with investment powder (like plaster of Paris). It is then heated in a heat chamber.

The heat will melt the wax and solidifies the investment powder. The liquefied metal is then poured into this container.

It is then allowed to cool and open to expose the jewelry, which is still in casting form.

Types of Jewelry Finishes

There are several techniques to create a jewelry finish. The most common are:

- High Polish

- Matte

- Satin

- Brushed

- Hammered

Embellishing and Setting

Once the creation is cast, the stones that are required for the design will be selected and sorted. The selection will consider the stone sizes and weights that will be appropriate for the final set. It is a time-consuming process and requires the knowledge of an experienced and skilled person

Once selected, it will be sent to the setting department. Using a microscope, the setting specialist will apply each gemstone to the cast material. This micro-setting process requires a steady hand, skill, and years of experience to get a perfect finish for this jewelry design.

The next stage is polishing and plating.

Note: If you want to polish your jewelry, use this Jewelry Cleaning Kit that I have used before, and it works.

Polishing and Plating

Deburring, polishing, and buffing can be considered the second to the last stage where the entire piece is carefully and painstakingly deburred, polished, buffed and cleaned to get the highest degree of smoothness and shine.

Deburring is removing the sharp edges, burrs, and air bubbles on the material.

Polishing is the use of specific abrasives to get a shinier surface finish. Different polishing materials are used for different metals. Hence, to polish gold, the material is different for platinum and silver.

Buffing is the next step after polishing. This is to get a high sheen and shine for the final finish.

Plating

The last and final process is plating. Once the item is polished, it is sent for plating using the electro-deposition process. Depending on the jewelry design, the plating can be with copper, gold, chromium, silver, rhodium or any other metals based on the approved design concept.

To increase the wearability and durability, rhodium is often used to plate white gold and platinum jewelry.

Gold is also used to plate silver and sold off as a piece of gold jewelry. You can still buy solid gold jewelry but it is more expensive.

Quality Control Check

Once plating is complete, it is sent to the quality control section for a thorough check for any defects. If there are any, it is sent back to the respective divisions for correction.

In some companies, the chief artisan does these inspections. For an expensive and elaborate jewelry design using rare or valuable gemstone such as Paraiba Tourmaline, the General Manager or CEO may even be part of the inspection team.

These jewelry pieces will not be released for sale until this team gives the seal of approval.

Jewelry and Fashion

The trend for jewelry and fashion changes every year, but not many people can afford to keep up with the changes in the jewelry trend. What's important is to know how jewelry is made. Why it can take several months to conceptualize and create a bejeweled piece, so you can appreciate and value your jewelry even more.

I've never thought of my jewelry as trophies. I’m here to take care of it and to love it, for we are only temporary custodians of beauty

— Elizabeth Taylor

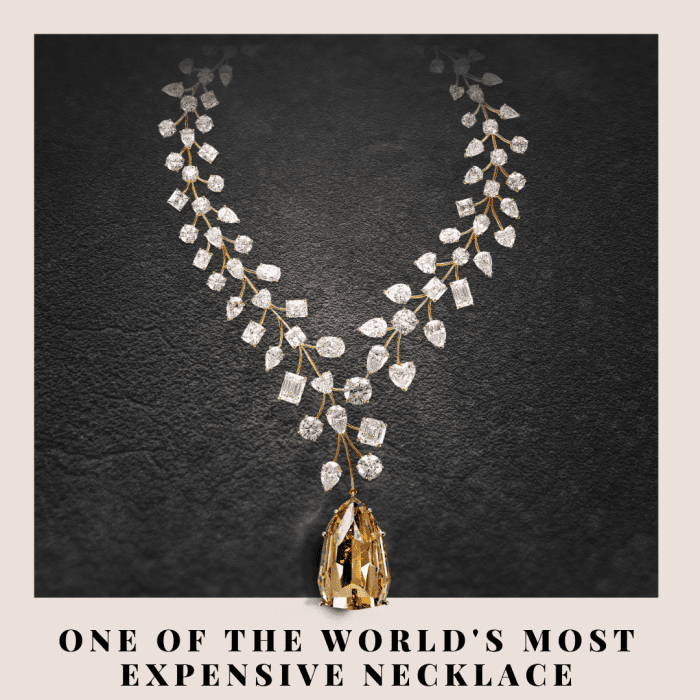

This stunning 637-carat L'Incomparable diamond necklace was sold for a record-breaking US$55 million in 2013 and at that time, was named the world's most expensive necklace by Guinness World Records

Fun Facts: The Most Expensive Jewelry Pieces in the World

The Mouawad‘s 637 carats L’Incomparable Diamond Necklace ranked as one of the world's priciest jewelry. This exquisite deep-yellow diamond centerpiece is the world’s largest internally flawless diamond. It weighed an amazing 407.48 carats and was discovered by a young girl in 1980 in the Democratic Republic of Congo.

It took over four years to craft and polish it before it was revealed to the public in 1984. This incomparable diamond is complemented by 90 other smaller diamonds of various cuts.

This content is accurate and true to the best of the author’s knowledge and is not meant to substitute for formal and individualized advice from a qualified professional.

© 2012 Mazlan A

Comments

yingchenchen from hz on July 21, 2020:

I really like the sharing of articles, you can check our company website when you have time https://www.nihaojewelry.com

Mazlan A (author) from Malaysia on November 15, 2012:

@thumbi7 Thanks for dropping by and for the kind words. Photos of jewelry always attract a woman's attention!

JR Krishna from India on November 15, 2012:

Very interesting information.

I liked the photos.

Thanks for sharing